How to bond sign channel to ACM blanks

This article provides a guide on effectively bonding sign channel to ACM (Aluminium Composite Material) blanks, a common task in the sign industry. It covers essential techniques, materials, and best practices for achieving a secure, durable bond.

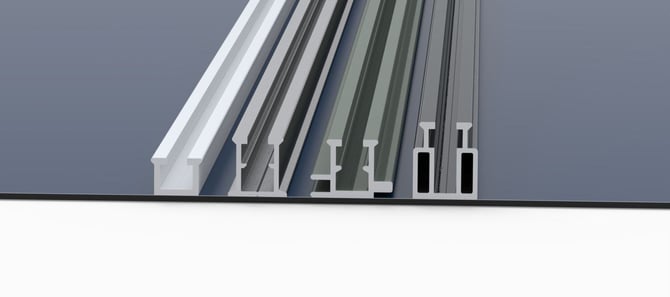

What is aluminium sign channel?

Aluminium sign channel is one of the most commonly used aluminium extrusions in the UK sign industry. It forms the backbone of many post and panel sign systems, with examples visible along every road in the UK, particularly as road signs. Additionally, it is widely used in commercial, retail, and wayfinding applications.

Once the aluminium sign channel is securely bonded to an ACM or aluminium sign blank, it can be paired with sign fixing clips, banding, and channel clamps to mount the sign blank onto vertical posts.

Once the aluminium sign channel is securely bonded to an ACM or aluminium sign blank, it can be paired with sign fixing clips, banding, and channel clamps to mount the sign blank onto vertical posts.

The sign channel is compatible with industry-standard anti-rotational sign clips and also universal channel clamps, which serve as the fastening method to securely attach the sign blank to posts, railings, or uprights.

Traditional Mechanical Fixing

Traditionally, mechanical fixings are used to secure the aluminium sign channels to the reverse of sign blanks. This is usually achieved using a flush rivet fixing, the stainless steel rivets are punched through the face of the sign blank and the channel which then leaves a flat surface on the sign blank to add the sign graphics using printed self-adhesive vinyl.

However there are some drawbacks to flush rivet fixing:

- Flush rivets require specialist machinery which smaller sign makers may not want to invest in.

- Graphic application can be more challenging after channel has been rivetted to the sign blank

- Although minimal, flush rivets are still visible on the sign face which some end users may dislike

- Rivets only provide fixing strength at the locations of

Bolhoff flush riveting machine in Sign Trade Supplies workshop

Structural Bonding Tape

Sign makers across the UK have brought the fabrication of sign blanks in-house by adopting the modern method of bonding aluminium sign channel to ACM/Aluminium sign blanks using structural bonding tape.

When applied correctly, structural bonding tape creates an exceptionally strong, permanent bond that is resistant to UV rays, weather, and temperature changes. This seamless bond not only leaves the sign blank blemish-free but also allows graphics to be applied to a flat panel before bonding the channel, streamlining the vinyl application process for speed and efficiency.

In addition, unlike traditional rivets, structural bonding tape distributes strength across the entire surface area of the channel, rather than concentrating it at localized points. This results in greater strenght, allowing ACM sign blanks to withstand higher stresses and impacts before failing.

Sign Channel Structural Bonding Method

The four step method involves cleaning, priming, taping and bonding. As with most jobs requiring adhesive bonds, preparation is key! So following the steps below are necessary for creating a bond that will last the life of the sign:

1. Cleaning - Both the sign channel and sign blank must be thoroughly cleaned and degreased with a strong solvent cleaner. The Stykra EXT cleaner has been designed specifically for this structural bonding method.

2. Priming - Once cleaned and degreased the aluminium sign channel and and sign blank should be primed using Stykra EXT primer or 3M 94 primer. This radically improves the overall bond strength, in some cases the bond strength can improve by 30%. It is important to use the primer sparingly and not over coat.

3. Tape application - Once your primer has fully dried (usually within 1-2 minutes of application at room temp) keep your channel free from dust or debris and apply the double sided tape carefully by hand. Apply firm even pressure over the tape as they are pressure activated. We recommend the Stykra 700 EXT tape that has been designed for application to low surface energy materials and at low temperatures

4. Bonding - Once your tape is applied and trimmed to your sign channel, mark out your sign blank, peel off the red liner and apply the channel to your blank. Be sure to apply firm even pressure along the length of the channel. Once applied there is a 48-72 dwell time until the full bond strength is achieved. We do not advise installing the sign before the full 72 hours bond time.

Want to see the bonding process in action ? Check out our instructional video below

In conclusion, aluminium sign channel plays a vital role in the UK sign industry, providing the structural foundation for numerous signage applications. By adopting modern bonding techniques, such as structural bonding tape, sign makers can achieve strong, durable bonds that outperform traditional methods like mechanical fixings.

The seamless application process not only enhances the aesthetic appeal of the signs but also improves their resilience against harsh environmental conditions. Following the recommended bonding steps ensures long-lasting, high-quality signage that meets the demands of commercial, retail, and wayfinding environments.

Helpful Documents: Stykra 650 Bonding Guidelines